Predictive & Preventive Maintenance Differences

The main maintenance strategies currently adopted in the maritime industry are:

Reactive Maintenance or Run until failure maintenance :

Adopted for not significant equipment where the cost of catastrophic failure could be mitigated.

Preventive Maintenance or Planned Maintenance

The required by IMO & IACS maintenance strategy where maintenance should be carried out at specified intervals based mostly on recommendations from the makers of the machinery or company's experience.

Preventive maintenance strategy was imposed by IMO as a strategy to increase reliability of the ships equipment and consequently the safe operation of the vessel. It is evident that after more than 20 years in force of the strategy the reliable operation, although improved noticeably, still remains uncertain and at a considerable high maintenance cost. Even if preventive maintenance plan is followed to the letter still catastrophic damages occur with grave financial costs. The reason is that the decisions for maintenance interventions are based at best, on equipment's performance and evaluation vs statistical data, and not on real time measurements which can more reliably indicate the actual condition of the equipment.

Another significant consideration is that preventive maintenance strategy can not easily be applied on many modern systems due to their nature, and as a result the maintenance costs to follow any maintenance plan are exorbitant or the maintenance plan is merely reduced to a beautified Run to Failure plan.

Predictive Maintenance.

Predictive maintenance is based on Condition measurements like vibration or particles contained in the oil measurements, in order to asses the health condition of a piece of a equipment.

Although Condition Based Maintenance methodologies were only recently accepted by IACS as approved maintenance strategies, condition measurements of oil properties and particles contained in the oil are broadly adopted by the shipping companies. Moreover vetting companies acting on behalf of charters have for many years now, required Condition Based Maintenance techniques or Predictive Maintenance Strategies to be adopted in conjunction with preventive maintenance as prerequisite in order the vessel to be approved as reliable and suitable for loading, specially tanker ships.

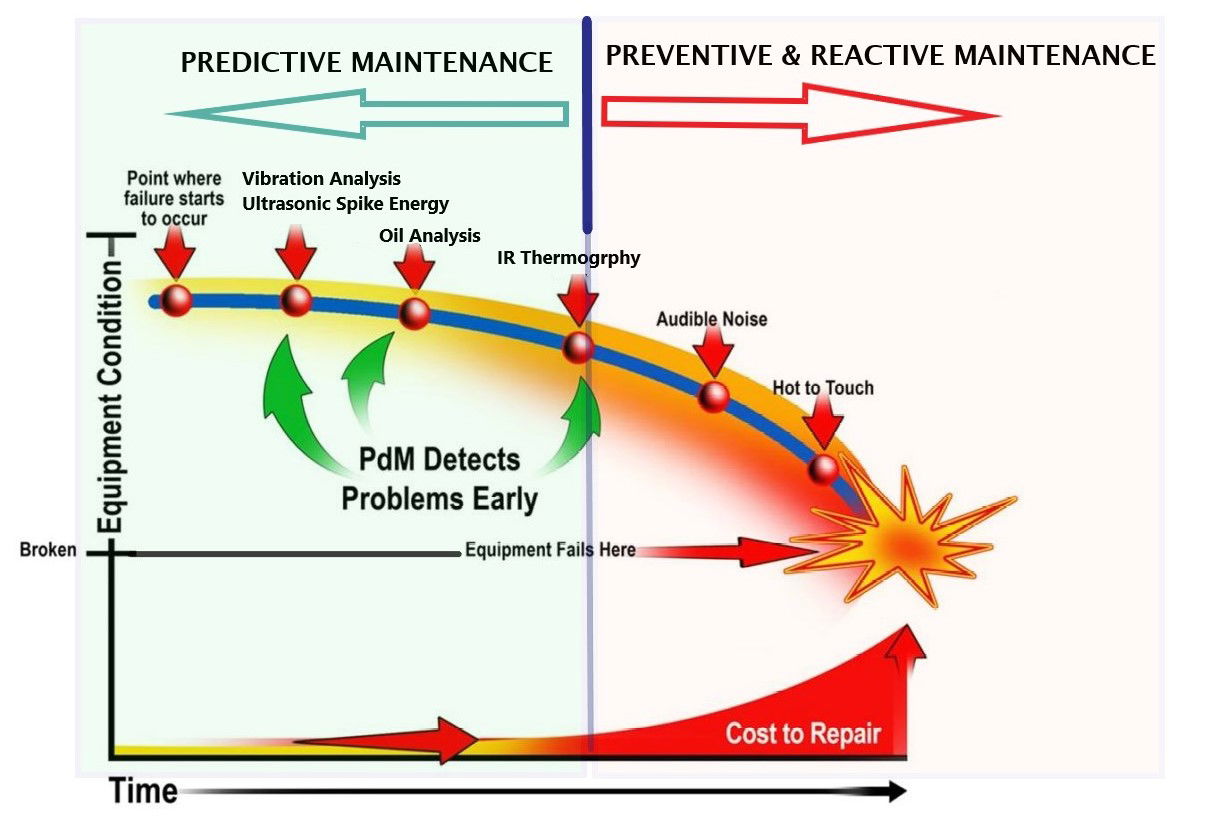

Below there is a self explained characteristic Curve of The Planed Maintenance Vs Preventive maintenance strategies and what it means in terms of cost for maintaining any piece machinery at an acceptable level.